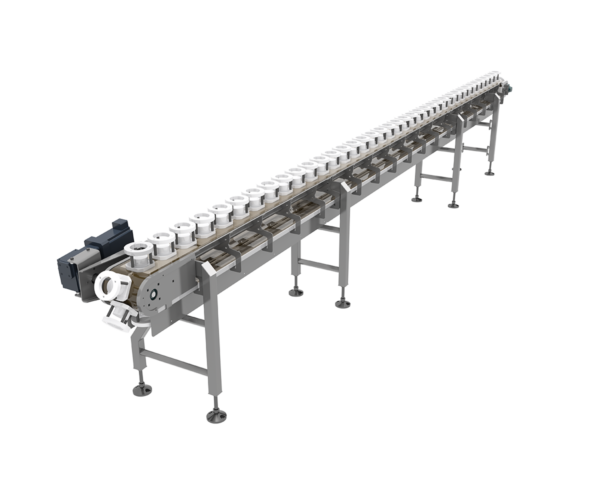

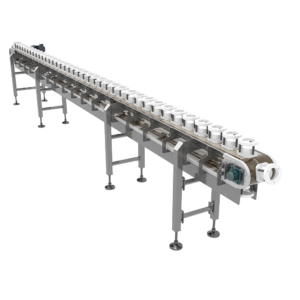

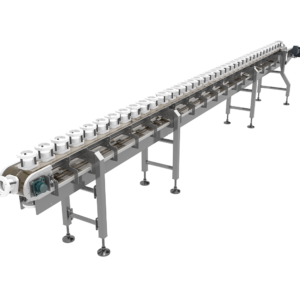

Wash Down Conveyor

NeXtgen®

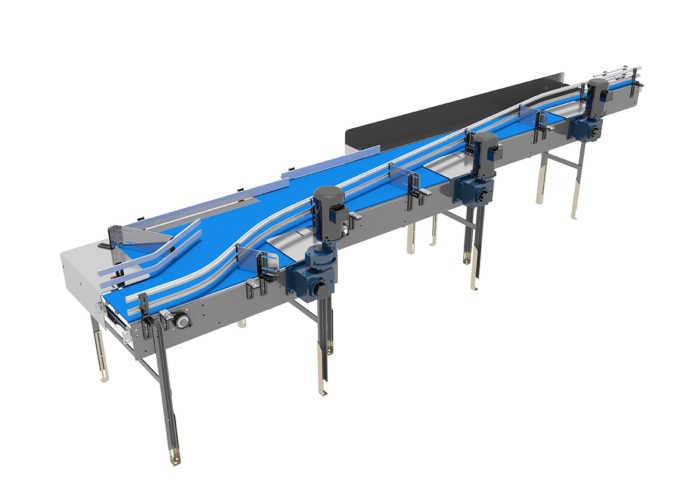

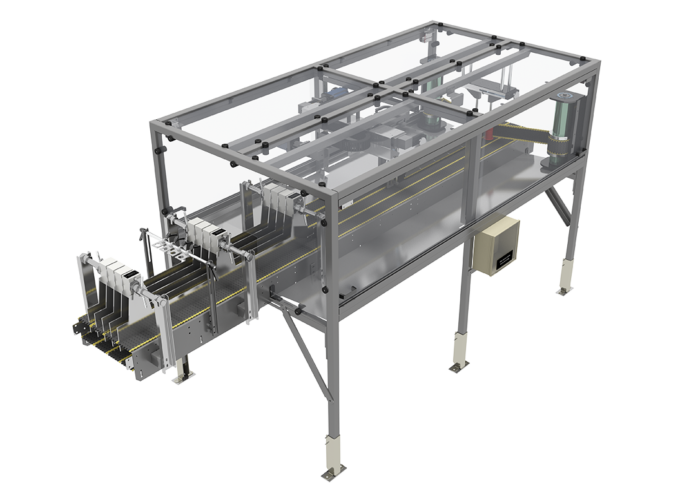

Reduce operating costs with NeXtgen’s patented open frame design that provides 100% visibility of product contact zones and enables fast, effective cleaning. The frame’s minimized horizontal surfaces also prevents contaminants from collecting. The wash down conveyor’s tubular back bone and web bracket frame design features a mounting hole every 12 inches along each side of the frame.

- Adjustability: Reconfigure modules to accommodate production line changes

- Function: Engineered to meet the unique handling needs of the food industry

- Features: Patented frame design minimizes surface-to-surface contact

Engineering Services

With A&B Engineering, you get 24/7 support, call 844-686-5589 for project management, training, installation, relocation and more.

Questions? Contact us today.

Machine Specifications

End Product Details

Type

Bottles, Cans

Shape

Non-Round, Round

Fill

Cold-Filled, Empty, Full, Hot-Filled

Material

Aluminum, Glass, Plastic, Steel

General Design

Modular

Yes

Frame

Open Frame

Material

Stainless Steel

Return

Roller, Serpentine

Modules

Idle Ends

.5', 1', 1.5', 2', 3', 4', 6', 8'

Drive Ends

.5', 1', 1.5', 2', 3', 4', 6', 8'

Inline Transfers

.5', 1', 1.5', 2', 3', 4', 6', 8'

Parallel Transfers

.5', 1', 1.5', 2', 3', 4', 6', 8'

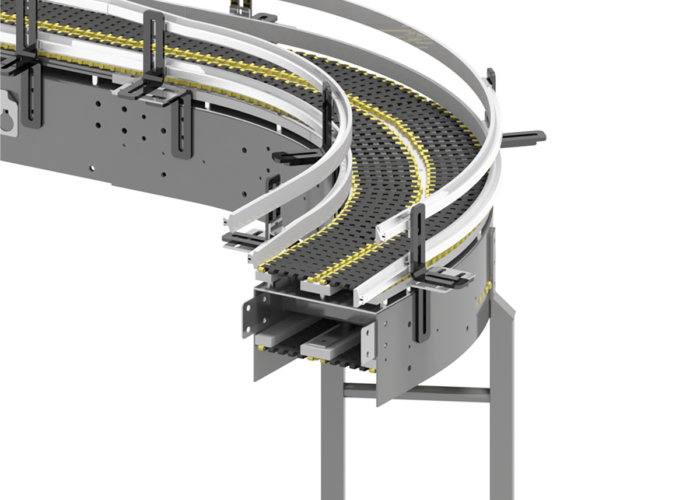

Turn Degree

15, 30, 45, 60, 75, 90, 180

Turn Radius (Inches)

18", 24", 30", 36"

Cope Type

Fixed

Cope Adjustment Increments (Degrees)

Fixed

Wearstrip

Type

UHMW

Motor/Drive

Type

Stainless Steel Wash Down

Type 2

Gear Motor, Inverter Duty

Style

Shaft Mounted

Supports

Material

Stainless Steel

Construction

Square Tube, Welded H Style, Formed Channel

Adjustment Type

Adjustable Foot

Adjustment Increment

+/- 3"

Warranty

Warranty

1 Year Warranty

Related Products

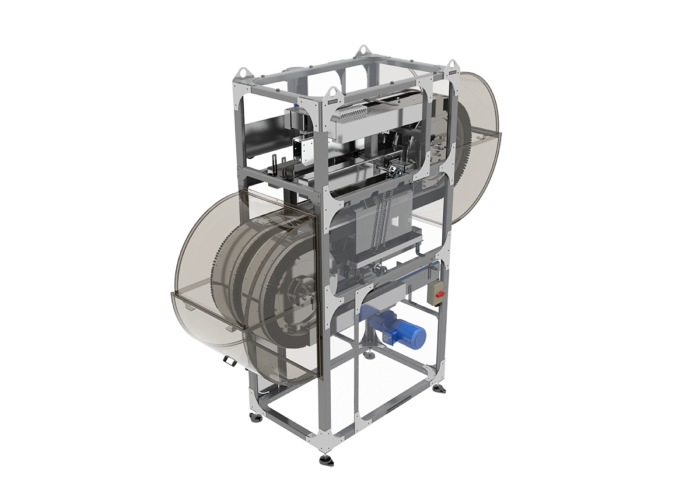

Engineered Solutions

Cutting Edge Technology

With A&B Engineering, you get 24/7 support.

New equipment not in the budget? A&B’s Engineering Services engineered solutions will extend the product life span of older, legacy equipment by modernizing your machines and increasing productivity.