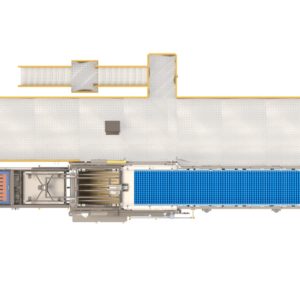

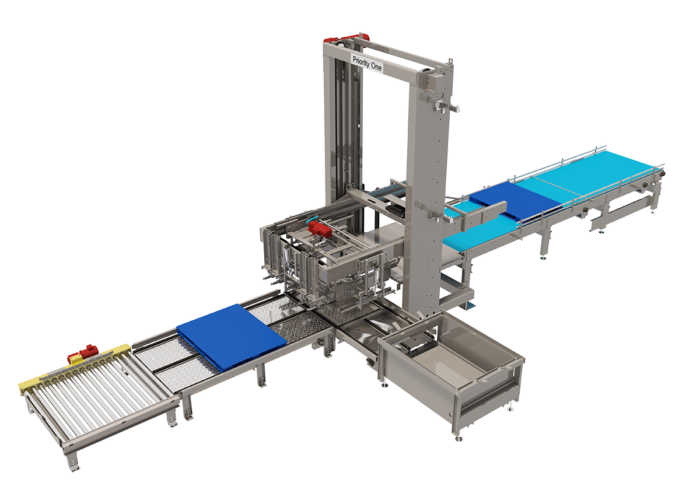

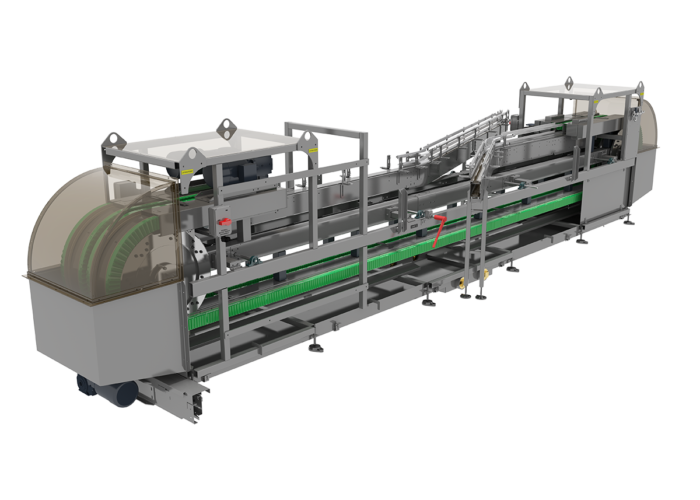

High Level Bulk Depalletizer

Alpha Turbo™

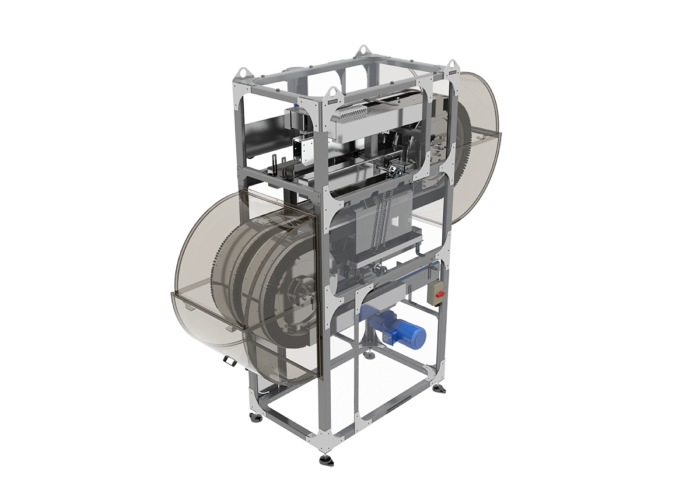

The Alpha Turbo™ High Level Bulk Depalletizer from Busse/SJI is the world’s most advanced Depalletizer offering a simple-to-use operator interface, as well as equipment and production data monitoring. With built in machine health monitoring, the Alpha Turbo™ gives users a way to monitor, in real-time, critical motion and pneumatic system parameters including airflow, pressure, vacuum, mechanical actuation speeds, and motor vibration.

- Speed: Process up to 10 layers per minute (depending on product)

- Simplicity: Simple design with few parts and maintenance friendly access

- Automation: Self diagnostics, energy monitoring, performance metrics and predictive maintenance

- Customizable : Optional packages layout/configurations available

Engineering Services

With A&B Engineering, you get 24/7 support, call 844-686-5589 for project management, training, installation, relocation and more.

Questions? Contact us today.

Machine Specifications

End Product Details

Type

Bottles, Cans

Shape

Non-Round, Round

Fill

Empty

Material

Aluminum, Composite Product, Glass, Plastic, Steel

Standard Equipment Specifications

Control Voltage

24 VDC

Electrial Power

460V/3Ph/60Hz

Compressed Air Volume, CFM (Liters/min)

8.4 SCFM @ 80psi (237.9 Liters/min @ 5.5 bar)

Machine Speed (SPM)

10 (pending container profile)

Maximum Load Height, Inches (mm)

110 (2790)

Maximum Load Weight, Pounds (kg)

Up to 4,000 Lbs.

Standard Pallet Size Inches (mm)

44 x 56 (1120 x 1420)

Optional Pallet Width Range, Inches (mm)

40 (1000)

Optional Pallet Length Range, Inches (mm)

48 (1200)

Minimum Pallet Conveyor TOC, Inches (mm)

12 (304)

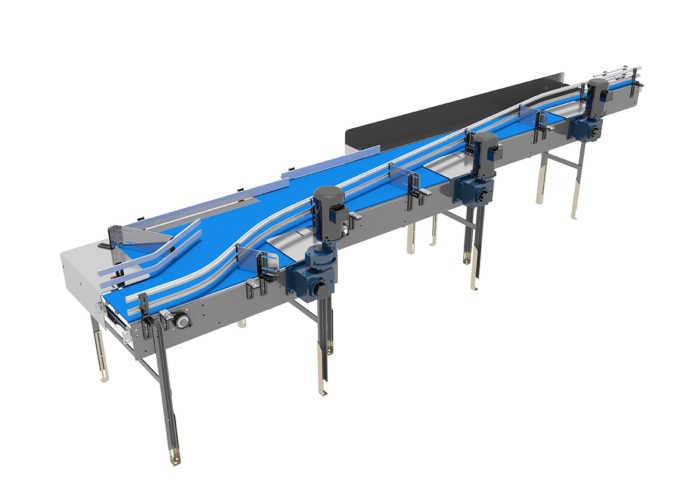

Standard Tin Line (TL), Ft (mm)

13 (3960)

Warranty

Warranty

1 Year Warranty

Optional

Alternate Tin Line and Top of Chain configurations

Electrical Power: 575V, 400V

Main Hoist Drawer: For capture of fallen containers

Quick Mechanical Adjustments

Second layer stabilization

Hoist block up kit

Flavor Change for efficient product changeover

Double Sheet Detection

Dunnage Options: Combined, separated or collated

Vacuum bar or row stripper discharge for non-round containers

Operator platform

Bed Covers

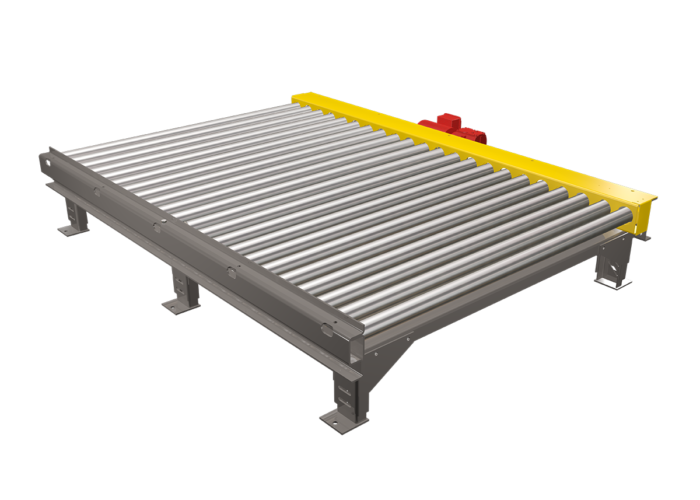

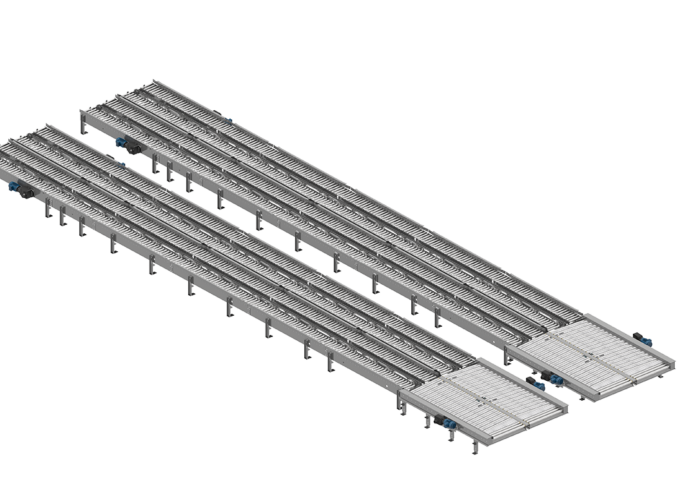

Related Products

Engineered Solutions

Cutting Edge Technology

With A&B Engineering, you get 24/7 support.

New equipment not in the budget? A&B’s Engineering Services engineered solutions will extend the product life span of older, legacy equipment by modernizing your machines and increasing productivity.