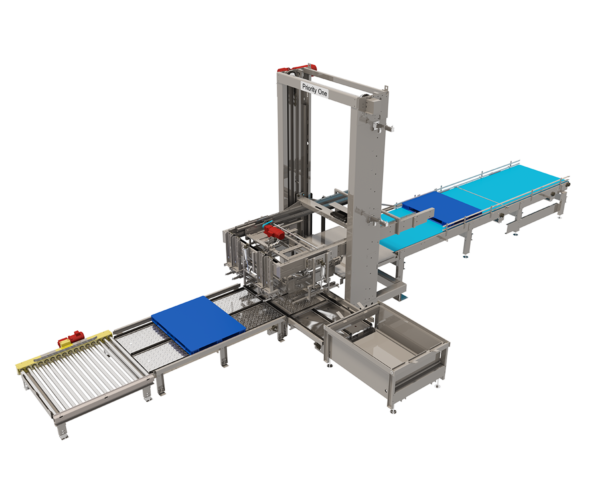

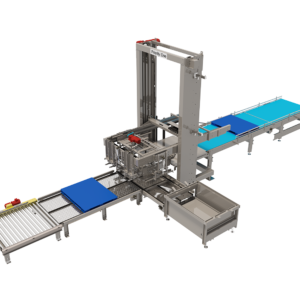

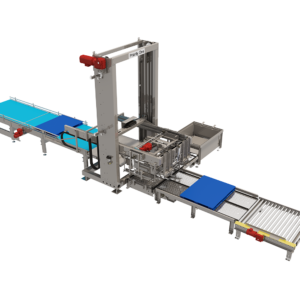

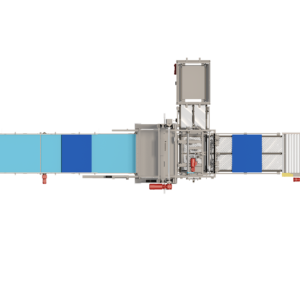

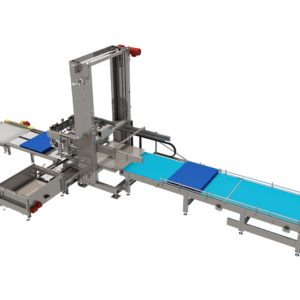

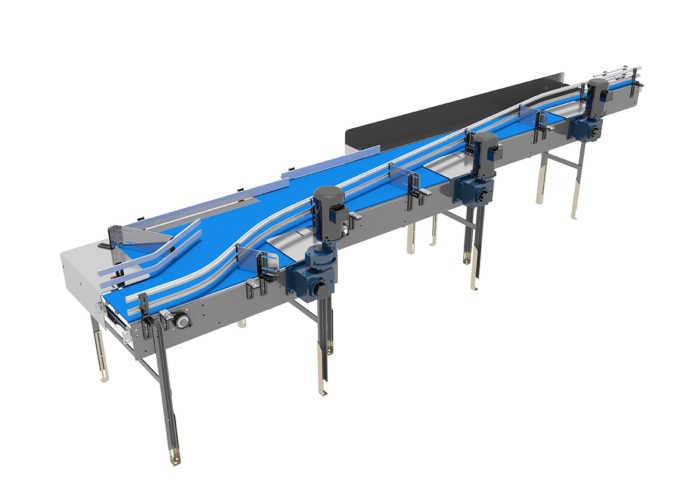

Low Level Bulk Depalletizer

Xodus™

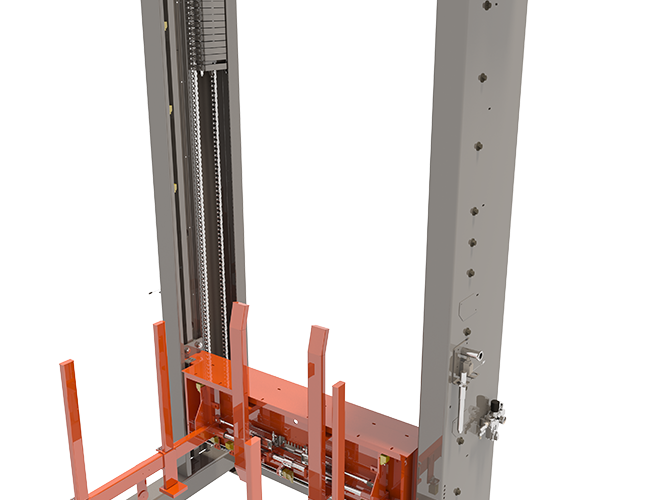

Maximize productivity with the Xodus™ Low Level Bulk Depalletizer. Perform product capture, sweeping and product discharge simultaneously to significantly reduce idle time and achieve maximum efficiency. Remove layers of containers from a pallet to accumulation tables or in-feed conveyors. This depalletizer requires minimal employee interaction—a single operator can perform container changeovers in just 15 minutes.

- Output speeds: Up to 3.4 layers per minute, including pallet change

- Variety: Multiple dunnage options

- Maximum Load: Up to 4,000 lbs.

- Customization: Multiple full pallet infeed configurations available (pending application)

Engineering Services

With A&B Engineering, you get 24/7 support, call 844-686-5589 for project management, training, installation, relocation and more.

Questions? Contact us today.

Machine Specifications

End Product Details

Type

Bottles, Cans

Shape

Non-Round, Round

Fill

Empty

Material

Aluminum, Composite Product, Glass, Plastic, Steel

Standard Equipment Specifications

Control Voltage

24 VDC

Electrial Power

460V/3Ph/60Hz

Compressed Air Volume, CFM (Liters/min)

4.54 SCFM @ 80psi (128.6 Liters/min @ 5.5 bar)

Machine Speed (SPM)

3.4 (pending container profile)

Compresses Air Inlet

3/4" NPT

Maximum Load Height, Inches (mm)

110 (2800)

Maximum Load Weight, Pounds (kg)

Up to 4,000 Lbs.

Standard Pallet Size Inches (mm)

44” x 56” (1120mm x 1420mm)

Optional Pallet Width Range, Inches (mm)

40 (1000)

Optional Pallet Length Range, Inches (mm)

48 (1200)

Standard Pallet Conveyor TOC, Inches (mm)

18 (457)

Minimum Pallet Conveyor TOC, Inches (mm)

12 (304)

Warranty

Warranty

1 Year Warranty

Optional

Electrical Power: 575V

Alternate Tin Line and Top of Chain configurations

Second layer stabilization

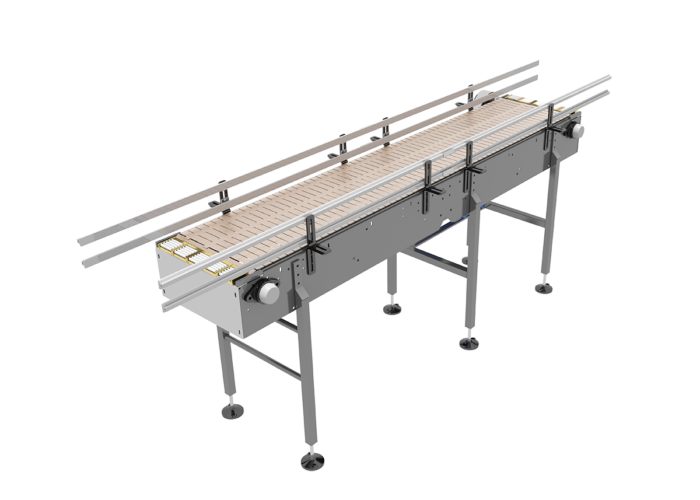

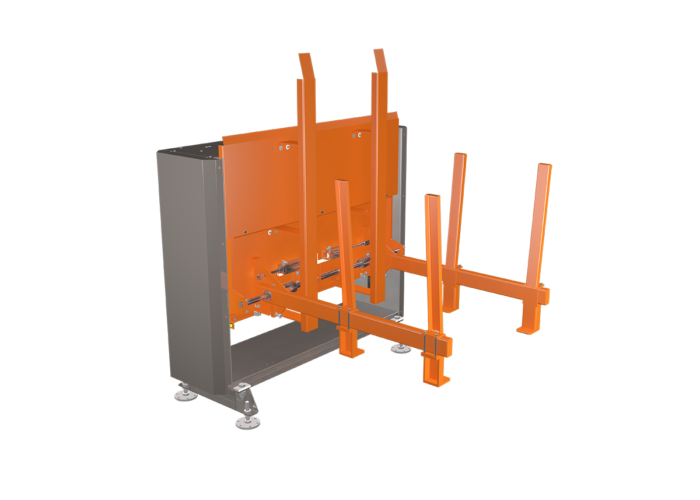

Related Products

Engineered Solutions

Cutting Edge Technology

With A&B Engineering, you get 24/7 support.

New equipment not in the budget? A&B’s Engineering Services engineered solutions will extend the product life span of older, legacy equipment by modernizing your machines and increasing productivity.